The solution for boosting your business and reducing cost at the same time

As a subcontractor, we are offering mechanical design outsourcing services

for international (outside Vietnam) customers.

Here are benefits of outsourcing.

・You can’t recruit new and good engineers because of location of business.

・Your staffs are too busy with daily simple tasks to invest time for developing new product.

・Labor cost for design is increasing.

We are professional of mechanical design especially for Factory Automation machines

Our engineers are highly experienced about designing Factory Automation machines,

drawings related to such a special purpose machines and JIG used in production line.

Mainly we use ICAD/SX(Fujitsu) which is ideal for designing automation machines,

but we can use other CAD if customers request.

We accept customer’s CAD data in various formats which are convenient for our customers.

Various outsourcing services customized for your need

Here are examples of mechanical design outsourcing services we are offering.

Not only these jobs, we can provide any kinds of mechanical CAD related jobs

based on request from customer.

If you have a question or are interested in our service,

please feel free to contact us from inquiry form at the bottom of this page.

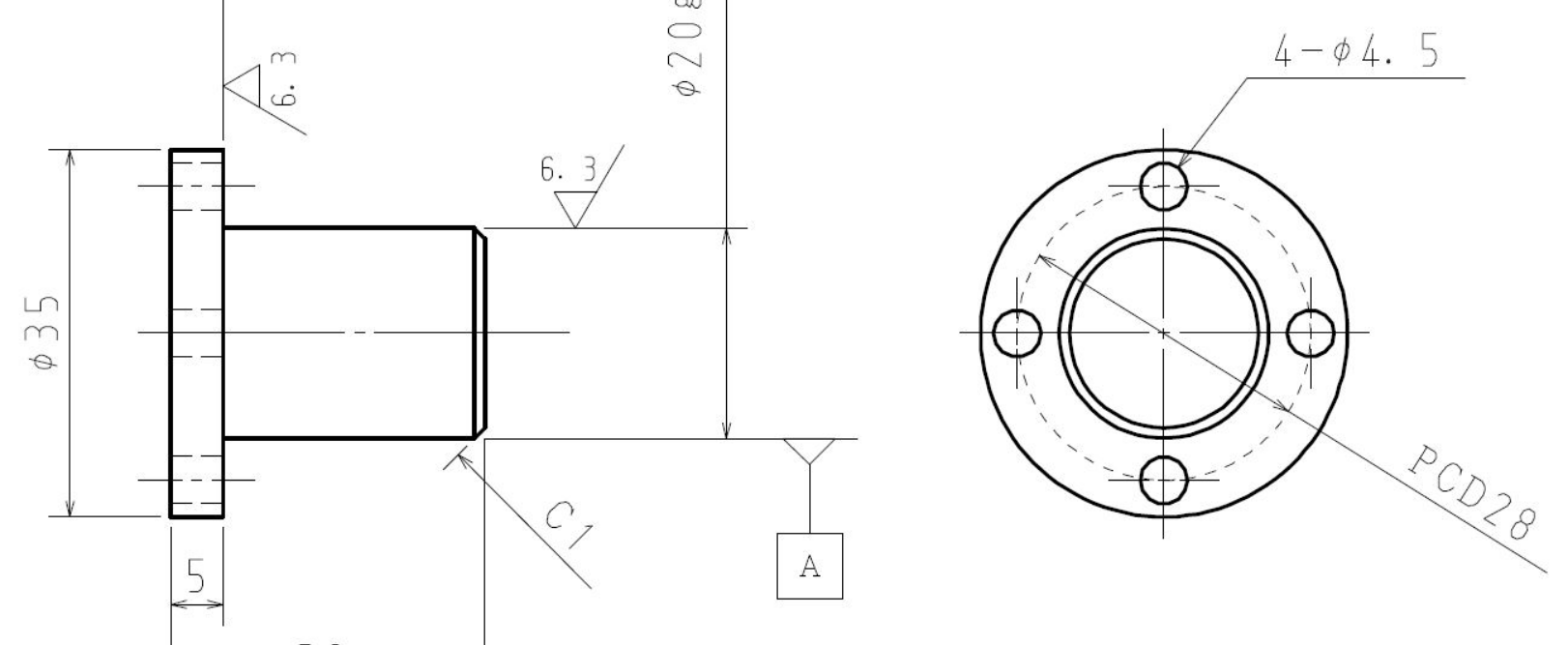

Make parts drawings from provided assembly drawing

We make 2D parts drawings for manufacturing from assembly drawing (2D/3D)

which is provided by customer.

We are experienced and care about detail such as

choice of material, tolerance and finishing because it’s the key for reliable machine in long run.

Also, we make parts lists for “purchasing parts” and “manufacturing parts”.

About simple and time-consuming jobs such as making parts drawings and parts list,

we do it, so that your company can focus on your core business.

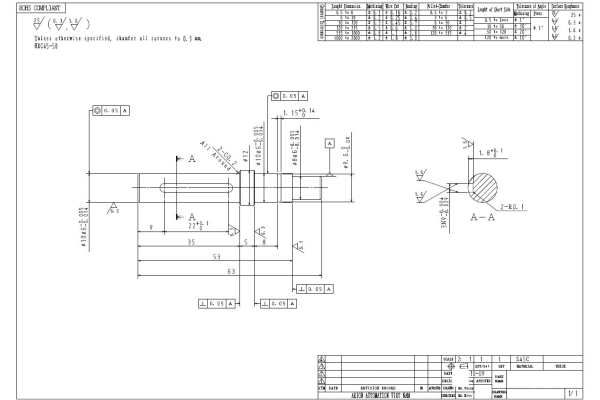

Making 3D model from 2D drawings

We make 3D model from 2D drawing, paper drawing or draft handwritten sketch

which are provided from customer.

We can make 3D model of small parts, assembly, whole machine or equipment

and pneumatic component layout etc.

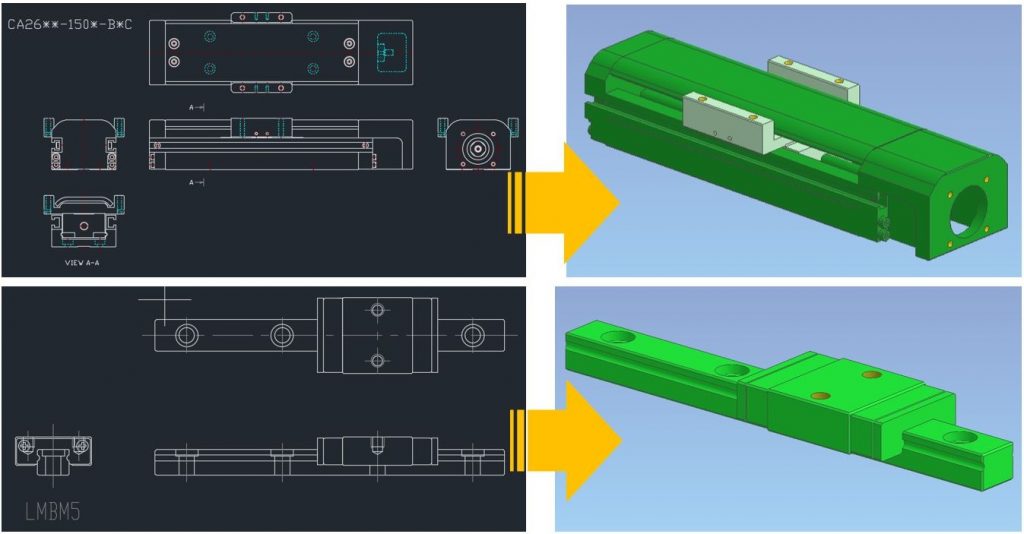

Designing machines customized for customer’s need

We design special machines based on customer’s purpose and request using 3D CAD.

We can design from draft(concept) level to assembly drawing, parts drawings and parts list.

- automation machine for special purpose

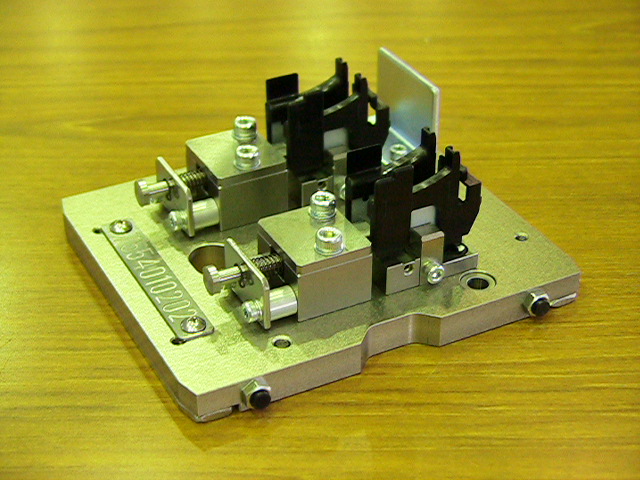

- JIG for manufacturing

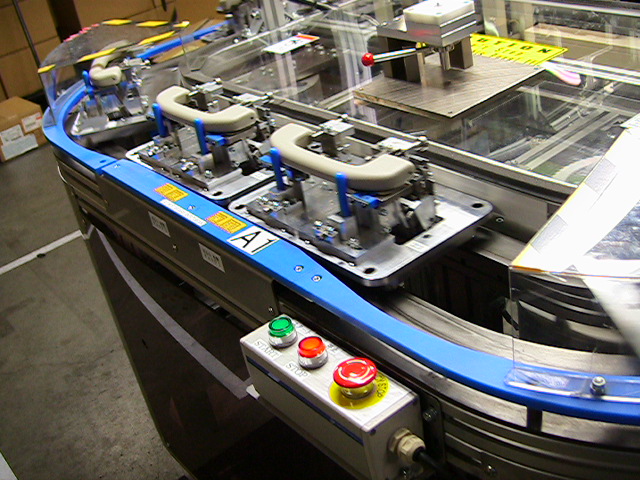

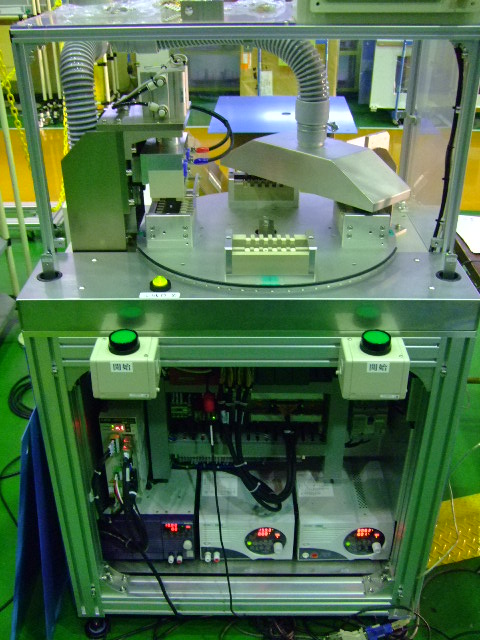

Automatic visual checking of electrical component by 2 sets of Keyence camera.

(*We outsourced machining parts and assembly to 3rd party supplier)

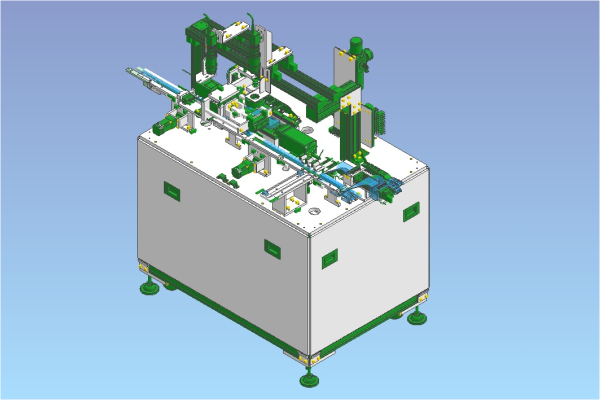

We have more than 30 years experience as professional of Factory Automation machine

Our headquarter in Japan, SAITAMA FUJI CO., LTD. has more than 30 years of history as a Factory Automation machine builder.

We offer high quality service for various purpose and need by our professional experience and knowledge.

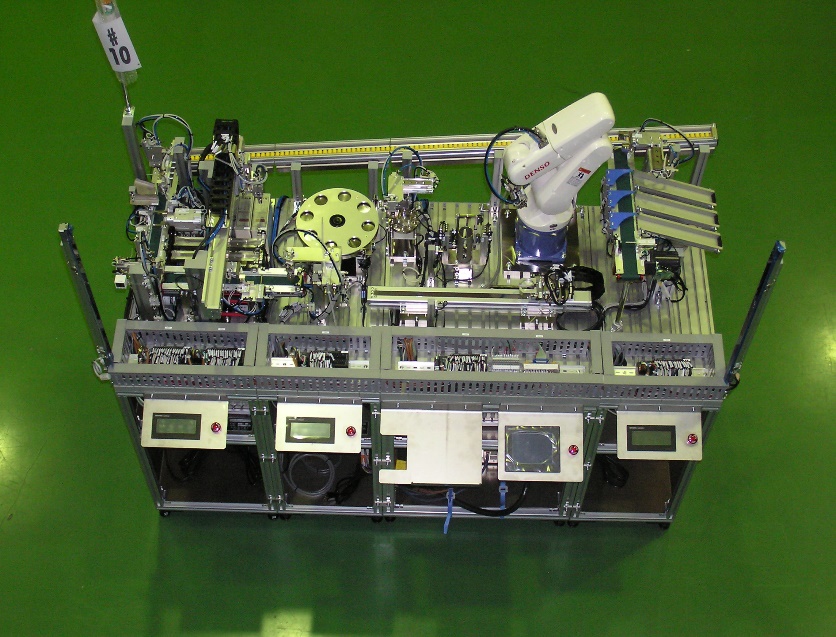

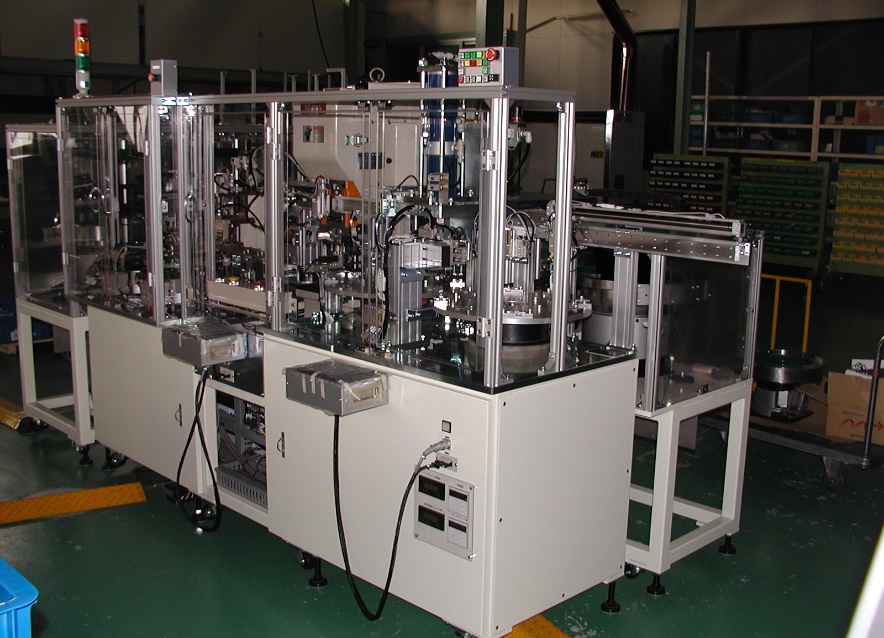

(for reference) examples of machines designed and manufactured by our Japanese headquarter, SAITAMA FUJI CO., LTD.

Japanese manager and technical adviser are stationed at our office in Vietnam

As a Japanese company, two Japanese are stationed at our office,

and take responsibility for delivery and design quality.

All drawings and CAD data are reviewed by Japanese technical adviser who have decades of experience in mechanical design.

Email by English is welcomed.

We can discuss and have a meeting using internet such as Skype.

Feel free to contact us.

+84-(0)-2471084488

Business hours 8:00~17:00(Vietnam)